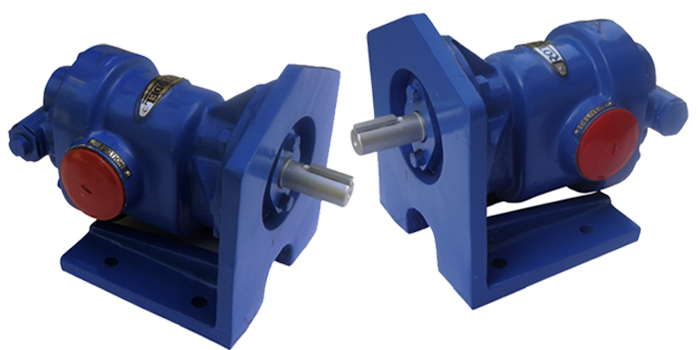

Rotary Gear Pump Type HGBX

Overview

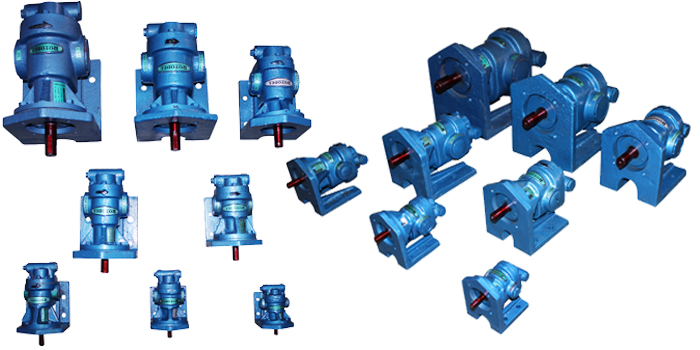

Capacity from 2.5 LPM to 400 LPM max. Working Pressure 11Kg/CM2, Temp. 90ºC Viscosity, 10,000 CST.

- Compact

- Low Noise

- Efficient

Foreword

ROTODEL rotary pump type "HGBX" is a self priming bi-directional positive displacement gear pump in simple two piece cast iron construction with single helical modified profile carbon steel gears shrunk fitted on alloy steel hardened & ground shaft as impeller firmly supported on 4 nos of seld-lubricated sintered bronze bush bearing. The pump can be run in either direction with change in Inlet-Outlet port position.The relief valve operations can be reversed by simply changning the R.V. parts on opposite side. The motorised pump-set in mono-block design ensures perfect alignment, saves space & reduces down time.

- 1) casing & covers - ci gr20, is-210

- 2) Drive shafts-EN-9 hardened & ground

- 3) Impeller gears-EN-8 toughened

- 4) Bush-Bearing-sintered bronze

- 5) Seals-Oilseals nitrile rubber

- 6) R.V. Spring- AISI S.S.302

- 7) R.V.Ball Valve-EN-31 hardened & ground

- 8) R.V. Screw & plug-Brass

- 9) Key for Coupling-Mild steel.

- For calculating power requirement, multiply unit hp per Kg Pressure with duty point pressure & add no load viscous hp of appropriate viscosity, adquate margin may be provided to this.

- Higher/Lower rating motor can be employed based on duty point power requirement than what is specified as above.

- Bracket in different height available to match the height of electric motor.

"HGBX" series pumps are designed to run at 1440 RPM up to viscosity of 500 CST, for higher viscosity it is desirable to reduce speed for sizes above 11/4". Performance at low speed is always advantageous as it improves efficiency reduces noise level & NPSHR & enhances operational life, Capacity will reduce in proportion to the speed.

H.P. Chart

| Pump Model & Size 'P.Q' BSP |

Capacity at 1440 RPM |

POwer Req. | WT. in KG. | |||||

|---|---|---|---|---|---|---|---|---|

| No Load Viscous hp |

Unit hp. per Kg. press |

|||||||

| LPM | US GPM | M3/hr | 200 CST |

500 CST |

Pump with Motor | Pump with L-Type Braket | ||

| HGBX-025 1/4" X 1/4" |

2.5 | 0.65 | 0.15 | 0.10 | 0.20 | 0.10 | 1.5 | 9.0 |

| 5.0 | 1.30 | 0.30 | 0.15 | 0.22 | 0.012 | |||

| HGBX-050 1/2" X 1/2" |

10.0 | 2.05 | 0.60 | 0.20 | 0.27 | 0.025 | 2.0 | 12.0 |

| 15.0 | 4.00 | 0.90 | 0.25 | 0.22 | 0.037 | |||

| HGBX-075 3/4" X 3/4" |

20.0 | 5.30 | 1.20 | 0.40 | 0.45 | 0.050 | 4.0 | 17.0 |

| 30.0 | 6.65 | 1.50 | 0.40 | 0.50 | 0.065 | |||

| HGBX-100 1" X 1" |

35.0 | 9.30 | 2.10 | 0.50 | 0.60 | 0.078 | 5.0 | 32.0 |

| 50.0 | 13.30 | 3.00 | 0.60 | 0.70 | 0.120 | |||

| HGBX-125 1 1/4" X 1 1/4" |

60.0 | 16.00 | 3.60 | 0.75 | 0.90 | 0.134 | 7.5 | 45.0 |

| 75.0 | 20.00 | 4.50 | 0.80 | 0.95 | 0.170 | |||

| HGBX-150 1 1/2" X 1 1/2" |

100.0 | 26.60 | 6.00 | 0.90 | 1.05 | 0.230 | 9.0 | 65.0 |

| 125.0 | 33.30 | 7.50 | 1.00 | 1.15 | 0.280 | |||

| HGBX-200 2" X 2" |

150.0 | 40.00 | 9.00 | 1.05 | 1.20 | 0.340 | 16.0 | 90.0 |

| 200.0 | 53.30 | 12.00 | 1.15 | 1.30 | 0.450 | |||

| 250.0 | 65.80 | 15.00 | 1.25 | 1.40 | 0.560 | |||

| HGBX-250 2 1/2" X 2 1/2" |

300.0 | 80.00 | 18.00 | 1.35 | 1.55 | 0.670 | 33.0 | 120.0 |

| 350.0 | 93.30 | 21.00 | 1.50 | 1.70 | 0.780 | |||

| 400.0 | 105.2 | 24.00 | 1.65 | 1.85 | 0.890 | |||

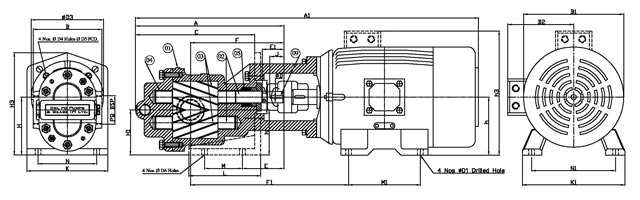

Dimension

| Pump Model & Size 'P.Q' BSP |

Pump & Pumpset Dimensions | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor hp & Frame Size |

Overall | Mounting | Shaft | ||||||||||||||

| A A1 |

B B1 |

C L |

H3 h3 |

D2 E |

D3 D4 |

D5 D6 |

d1 B2 |

F F1 |

K K1 |

M M1 |

N N1 |

D D1 |

E1 J |

H H1 |

h h1 |

||

| HGBX-025 1/4" X 1/4" |

0.50 | 118.5 | 64 | 88 | 107 | 45 | 72 | 59 | 8.0 | 74 | 78 | 35 | 60 | 09 | 25 | 63 | 71 |

| 0.71 | 368 | 145 | 77 | 170 | 47.5 | 6.8 | 8.0 | - | 163 | 136 | 90 | 112 | 11.0 | 18 | 53.5 | 61.5 | |

| HGBX-050 1/2" X 1/2" |

0.75 | 158.5 | 70 | 123 | 120 | 52 | 82 | 66 | 10.5 | 96 | 90 | 40 | 70 | 11 | 30 | 71 | 80 |

| 80-M | 443 | 165 | 91 | 200 | 61.0 | 8.5 | 8.0 | - | 199 | 152 | 100 | 125 | 13.0 | 25 | 58.5 | 67.5 | |

| HGBX-075 3/4" X 3/4" |

1.00 | 196.0 | 80 | 153 | 134 | 60 | 92 | 75 | 10.5 | 123.5 | 108 | 45 | 85 | 13 | 35 | 80 | 80 |

| 80-M | 481 | 213 | 110 | 200 | 63.0 | 8.5 | 10.0 | - | 228 | 152 | 100 | 125 | 16.0 | 25 | 66.13 | 66.0 | |

| HGBX-100 1" X 1" |

2.0 | 204.0 | 90 | 158 | 150 | 68 | 100 | 83 | 10.5 | 131 | 120 | 50 | 93 | 16 | 35 | 90 | 90 |

| 90-L | 544 | 195 | 125 | 186 | 66.0 | 10.5 | 10.0 | 150 | 251 | 168 | 125 | 140 | 19.0 | 25 | 73 | 73 | |

| HGBX-125 1 1/4" X 1 1/4" |

3.00 | 244.0 | 100 | 196 | 168 | 75 | 115 | 94 | 125 | 157 | 145 | 60 | 105 | 19 | 40 | 100 | 100 |

| 100-L | 624 | 215 | 155 | 250 | 67.0 | 10.5 | 12.5 | 160 | 299 | 192 | 140 | 160 | 22.5 | 32 | 80.5 | 80.5 | |

| HGBX-150 1 1/2" X 1 1/2" |

5.00 | 263.0 | 108 | 203 | 190 | 85 | 125 | 105 | 12.5 | 165 | 150 | 70 | 115 | 24 | 45 | 112 | 112 |

| 112-M | 668 | 235 | 160 | 275 | 81.0 | 10.5 | 12.5 | 170 | 314 | 222 | 140 | 190 | 23.5 | 35 | 90 | 90 | |

| HGBX-200 2" X 2" |

7.5 | 323.5 | 142 | 253 | 232 | 100 | 148 | 125.0 | 12.5 | 210 | 190 | 100 | 140 | 24 | 55 | 132 | 132 |

| 132-S | 793 | 275 | 196 | 320 | 95.0 | 14.0 | 15.0 | 190 | 404 | 254 | 140 | 216 | 28.0 | 40 | 105 | 105 | |

| HGBX-250 2 1/2" X 2 1/2" |

10.00 | 382 | 160 | 298 | 260 | 115 | 165 | 140 | 12.5 | 242 | 210 | 120 | 155 | 27.0 | 70 | 160 | 132 |

| 132-M | 892 | 275 | 222 | 320 | 108.5 | 14.0 | 18.0 | 190 | 438 | 254 | 178 | 216 | 31.0 | 45 | 128 | 100 | |

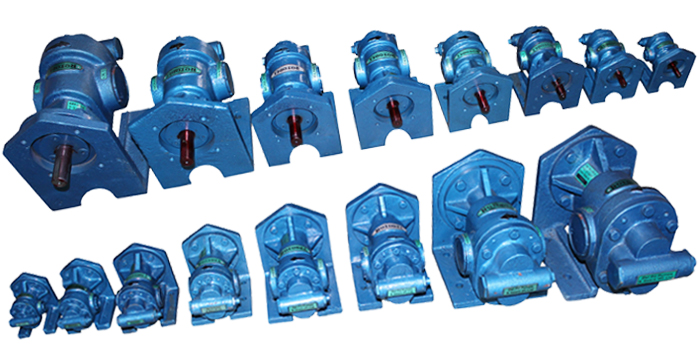

Uses

Due to simple & compact design & with mono-block version these pumps are ideally suitale for OE application of engine lubrication, pumping & heating units, oil filtration, cleaning & cooling systems. The pump can also be used for general purpose application to handle viscous liquid such as fuel oil, lube oil, LSHS, mineral oil, transformer oil, LDO paints, varnish, glue, glycerine, soap solution, sugar solution & molasses.